Introduction

Challenges in Connector Testing:

Increasing complexity of connector designs due to miniaturization and multi-functionality.

High demand for precision and repeatability in testing force, displacement, and durability.

Need for cost-effective, automated testing solutions to reduce human error and improve productivity.

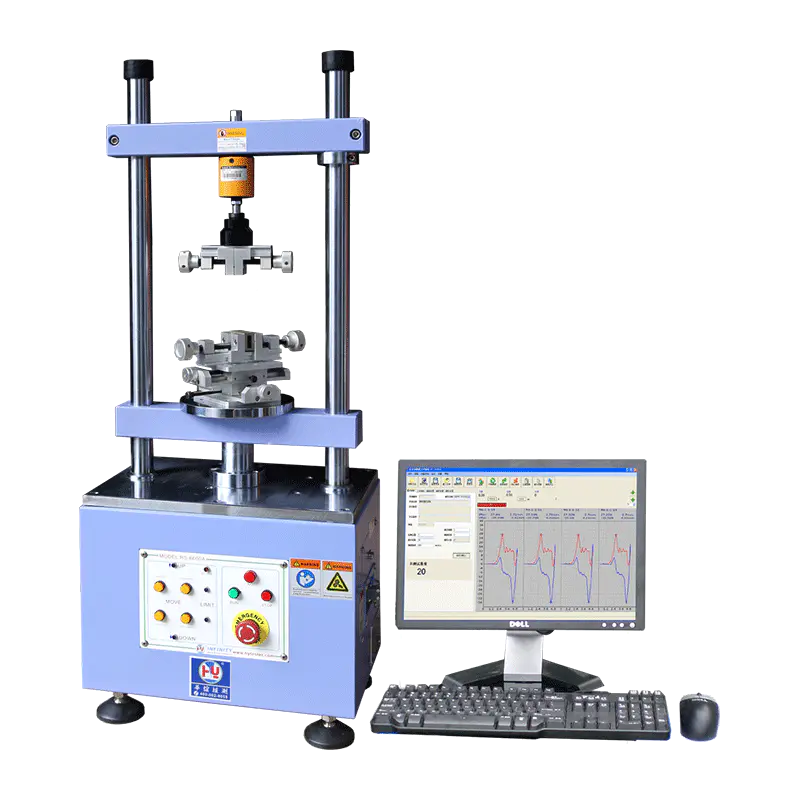

The Role of Advanced Testing Solutions: Testing devices like the RS-6600A enable manufacturers to meet stringent quality standards while ensuring product reliability and durability. These capabilities are particularly critical for industries where connector failure could have severe consequences, such as in aerospace or medical devices.

Key Features of the RS-6600A

Comprehensive Testing Capabilities

Connector insertion and extraction force testing.

Dynamic impedance testing for real-time signal performance monitoring.

Durability testing to simulate real-world stress and wear over time.

Single PIN and plastic retention force testing.

Compression force testing for connector springs.

High Precision and Accuracy:

Equipped with a high-precision load cell, ensuring ±0.5% accuracy.

Minimum force display: 0.01kgf or 0.01gf.

Displacement resolution: 0.001mm.

Automation and User-Friendly Operation:

Fully automated testing process with Windows-based software interface.

Easy-to-use setup for test parameters, including force, speed, and displacement.

Automatic data storage and reporting, including load-stroke curves and durability graphs.

Adaptability for Industry Needs:

Configurable capacity options (5kgf to 100kgf) to suit different applications.

Adjustable testing speed (0-200mm/min or 400mm/min).

Compact dimensions and robust design for flexible deployment.

Applications Across Vertical Markets

1. Electronics Manufacturing:

Testing connectors used in smartphones, laptops, and wearable devices.

Verifying the durability and signal integrity of USB, HDMI, and other interface connectors.

2. Automotive Industry:

Ensuring the reliability of connectors in engine control units (ECUs), infotainment systems, and safety-critical components.

Testing the retention force and durability of high-vibration connectors used in harsh environments.

3. Aerospace and Defense:

Precision testing of connectors for avionics systems and mission-critical applications.

Ensuring compliance with rigorous aerospace quality standards.

4. Medical Devices:

Testing connectors for imaging systems, diagnostic equipment, and patient monitoring devices.

Ensuring biocompatibility and reliability under repetitive use conditions.

5. Telecommunications:

Verifying the performance of high-frequency connectors in 5G base stations and fiber-optic systems.

Testing connector durability in outdoor environments.

Competitive Advantages of the RS-6600A

1. Automation and Efficiency:

Compared to manual testing solutions, the RS-6600A reduces testing time and eliminates human error, ensuring consistent and repeatable results.

2. Versatility:

Its wide range of testing capabilities makes it an all-in-one solution, reducing the need for multiple specialized devices.

3. Cost Savings:

The RS-6600A’s durability and adaptability reduce long-term operational costs for manufacturers by minimizing downtime and the need for recalibration.

4. Compliance with Industry Standards:

Meets or exceeds testing requirements set by international quality standards, including ISO, IEC, and MIL-STD specifications.

Case Study: Improved Efficiency in Connector Testing for Automotive ECUs

Background: A global automotive supplier faced challenges in maintaining the reliability of connectors used in their engine control units. Manual testing methods were time-consuming and prone to inconsistencies.

Solution: The RS-6600A was implemented to automate the insertion and extraction force testing process, ensuring high precision and repeatability.

Results:

30% reduction in testing time.

Improved accuracy and consistency of test results.

Enhanced product quality and customer satisfaction.

Implementing the RS-6600A in Your Workflow

1. Initial Setup:

Quick and easy installation with minimal training required.

Pre-configured testing templates for common connector types.

2. Ongoing Operation:

Real-time monitoring of testing data via the intuitive software interface.

Automatic generation of detailed test reports for quality assurance and auditing.

3. Maintenance and Support:

Low-maintenance design with robust components.

Comprehensive after-sales support, including calibration services and software updates.

Conclusion

The RS-6600A Fully Automated Insertion & Extraction Force Tester is a transformative solution for connector testing across multiple vertical markets. By offering unparalleled precision, efficiency, and adaptability, it empowers manufacturers to meet the evolving demands of their industries while ensuring product quality and reliability.

To learn more about how the RS-6600A can revolutionize your connector testing processes, visit our website at https://www.itm-lab.com/product/servo-control-automatic-tester-rs-6600a.html or contact our sales team at sales2@itm-lab.com. Request a demo today to experience the future of connector testing firsthand!